ECO & ENGINEERING CHANGE ORDER

Engineering Change Order (thủ tục thay đổi kỹ thuật) designed to control engineering changes incorporated into the company product lines. ECO is a document that specifies either new product design details or proposed changes (mục đích thay đổi) to existing products. An ECO provides the ability to accurately document, authorize, and assess if the request is beneficial to your company. ECO controls item revisions and bill of material changes.

The Eco: The Engineering Change Order process provides for review of proposed changes requiring engineering decision and ensures orderly incorporation of approval design changes. The process begins with the need for change —» Development of the change —» Planning of how the change is to be implemented —» Official approval for the entire change package. The change process applies to all products are in Pre-production and Production release.

ECO – THE PREP GUIDELINES

Identify the Issue and Assess the Scope. The ECO is an approval and implementation (thi hành, bổ sung) process. The initial step of the process begins with the recognition of an issue that needs to change. An ECO can be triggered by one of the following causes in the manufacturing operation or other reasons:

- Customer Requirement: The customer is the role that requests a change due to problems encountered or new functionality requirements; this can be a person or an organizational entity and can be in- or external to the company that is asked to implement the change.

- Engineering Specification Waiver (ESW). A correction to a performance or safety deficiency for systems in the field. It is provided to the customer at no cost.

- Production Bill of Material from an approved/verified engineering’s model/assembly.

- Part tolerance issue or Part drawing dimension changes

- Official approval for the entire change package

- Procurement process (quá trình hoàn lại). Supply chain management, sourcing raw materials, and meeting purchasing goals.

- Tooling

SPONSORED CONTENT

Your Service Flyer

Your Event Invitation

Your Promotion Ads

Your Logo & Brand

Support us and grow your business with us. My goal was to make technical information available with ready access to commonly needed resources, formulas, and reference materials while performing my work as a Technical Support Engineer. The businesses listed in Sponsored Content were carefully selected because of their uniqueness. However, non-sponsored selected ads will be rotated monthly.

ViBa Direct lacks an advisory board to do research and hire writers with the latest technical knowledge. Creating an effective advisory board requires more than an invitation. Without your sponsorship, this is not possible. If your company is interested in placing the company’s logo, brand, event invitation, and other promotional banners and flyers here or on any other pages, please reach out to Customer Service for more detail.

A modified BOM is typically used to either schedule future engineering changes or to keep track of past ones. Therefore, a BOM plays a big part in the engineering change order process, it provides us a mechanism to evaluate the positive (đánh giá điều có thực) or negative effects the engineering change has made. It is visual and gives a design engineer, quality control manager, or process engineer the baseline to make sound business decisions. The person assigned responsibility for planning change must:

- Undertake the front-end analysis (đảm nhận thực hiện phân tích)

- Interface personally with all functional groups necessary to assure complete integration (đảm bảo hoàn thành hệ thống thống nhất) before the ECO is processed

- Ensure appropriate departments (bảo đảm bộ phận thích hợp) must fill out the ECO Form and completing it

Engineer's Documents:

- Engineering Drawing: An engineering drawing is a type of technical drawing/graphical language that is used to convey information about an object. Blueprints, manufacturing prints, dimensional prints, drawings, mechanical drawings, electrical drawings, or schematics are documents specific outline to show all the information and requirements needed to manufacture a part or product.

- Bills of Material: A comprehensive list of parts, items, assemblies and other materials required to create a product, as well as instructions required for gathering and using the required materials. A Bill of Materials can be comprised of three items: Components, Sub-assemblies, and Phantom BOM’s.

- Specification, Standard: A specification is a requirement which is clearly stated the necessary features in the design of a part/component/device or machine. A standard is a set of normal requirement, quality, level, grade by an authority as a basis of comparison.

- Wire List, Diagram: A wire list data set can include both cables and wires. The data file contains the actual wire and cable wire data to import into the active harness assembly to establish connectivity. A diagram shows the components of the circuit as simplified shapes, and the power and signal connections between the devices. A wiring diagram usually gives information about the relative position and arrangement of devices and terminals on the devices, to help in building or servicing the device.

- Other documents related to engineering are work instructions, assembly instructions, test instructions, assembly manuals, ect.

Document Control and Type:

- Prototype Document (not released to manufacturing) is not controlled by the ECO System. A prototype is an early sample, model, or release of a product built to test a concept or process. It is a term used in a variety of contexts, including semantics, design, electronics, and software programming. A prototype is generally used to evaluate a new design to enhance precision by system analysts and users. Revision number should be 2-characters revision number. Engineering must use “X1” to control revision as “Engineering Release”. Engineering Release documentation shall comply with Drafting Standards for maintaining changes.

- Pre-Production Document is controlled by the ECO System. Alpha-numeric revision identifiers always start with the letter “A” followed by sequential numbers (A1, A2, A3 through A9). If revision exceed A9, drop the “A” and continue the numerical sequence (10, 11, 12, 13, etc.) to control revision as “Preliminary Release”.

- Production Document is controlled by the ECO System. Proposed changes are subject to CCB review. Maintenance of Production Released documentation shall comply with Drafting Standards.

To avoid potential design, manufacturing, and inventory errors or miscommunications with the teammates and suppliers, the ECOs need to create in a clear, organized format that translates across departmental lines.

1. Create an Engineering Change Request. The Originator needs to complete an ECO form whenever the need for a product enhancement, replacing an obsolete, end of life component or a fix is identified. An ECR should include data and justification for the proposed change. This step also assesses the benefits and costs of going through with the change, and it lists the necessary resources to implement new processes identifying any related risks.

2. Review and Approve the ECR. The ECR form is circulated and reviewed among key engineering teams before it’s shared with extended product teams typically. Once the ECR is approved, it producs an engineering change order (ECO), which further describes the details of the proposed change and allows for a more formal review and approval process with all teams that will be involved in planning, procuring, testing, assembling, and supporting the final product.

3. Create an Engineering Change Order. The ECO is created to specifies either new product design details or proposed changes to existing products. ECOs provide a list of all the components, assemblies, and other documents that are affected. Submit the form to the Change Control Board (CBC) including engineering, quality, procurement, manufacturing, and external design teams or supply chain partners for review.

4. Review and Approve the ECO. After an ECO’s completion, there is another review as well as an approval stage. Depending on the scope of the work, it may require several approvals from various individuals. However, once the stakeholders provide their consent, senior management can provide overall authorization.

5. Notify Applicable Personel. The Engineering Change Notice (ECN) provides details of the change permissions and steps that will occur. It’s essential to communicate the ECN to all personnel affected by these changes after the ECO’s final review and approval.

6. Implement the Changes. Now that the engineering change proposal is through all steps, pertinent reviews, and approvals, changes can be implemented. Every team is provided their specific responsibilities and roles necessary to perform modifications. At this point, both the ECN and ECO become critical documents that guide the implementation of tasks. You can implement all revised items on an ECO, or implement each revised item on a different date.

THE ENGINEERING CHANGE ORDER (ECO)

Department Each department shall be responsible for creating new document and drafting proposed changes to documents required for operations specific to its functions.

- The Originator/Creator needs to complete an ECO form (see ECO Preparation Procedure). Responsible for verifying that the proposed documents or document changes are adequate and appropriate.

- Submit the form to the Change Control Board (CBC) for review. Distribute the ECO package to affected, sustaining engineers only

- CCB member review ECO package for: Content, Application, etc.

- CBC member review ECO package for: Design, Cost, Manufacturing, Field Implementation and Approve ECO. All COs must be approved by the appropriate Department Manager(s), Engineer(s), or their designee with advanced knowledge of CO subject matter.

- Approval managers/engineers signs off on ECO

- Process engineer/technician enters ECO data into MRP system

- Assign implementers and Implement (thi hành, bổ sung, thực hiện) ECO

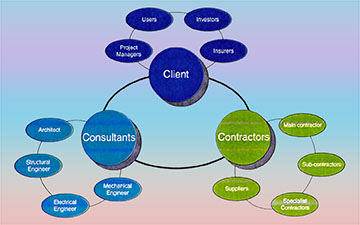

The Change Control Board (CCB): Or the Change Committee decides whether a Change Request will be implemented or not. Sometimes this task is performed by the project manager as well.

- Management: Chairperson (người chủ trì), Master Scheduler, Marketing, Finance and Cost Accounting

- Project Manager: The project manager is the owner of the project that the Change Request concerns. In some cases there is a distinct change manager, who in that case takes on this role.

- Engineering: Test Engineering, Design Engineering, Product Safety, Material, Software Engineering

- Manufacturing Approval: Manufacturing Engineering

- Quality Approval: Quality Assurance, Final Test

- Documentation: Technical Publication, Technical Drafting, Technical Writing

Change Control Board Responsibilities: The Change Control Board must approve all maintenance and revisions to the company policy, using the ECO process.

- Convene regularly (triệu tập thường xuyên) schedule CCB meeting, CCB Chairperson determines the event of meetings based on the ECO backlog (tồn đọng). CBC meetings are not for problem identification

- Review, discuss, approve, or reject ECOs and ECO process

- Provide justification (cung cấp lý do cho là đúng) for rejected or rescheduled ECOs

- Approve the effectivity (tán thành có hiệu quả; có hiệu lực) of the change or recommend a modification

- Record all CCB meetings in the form of Minutes or other appropriate documentation

- Assure accuracy and completeness of the ECO documentation

CCB Administration Controls:

- Issue ECOs for review to CCB Members, three to five working days before a scheduled CCB meeting

- Provide CCB Meeting Minutes by the last working day in every week

- Provide Agenda (cung cấp chương trình làm việc) and Minus to other interested parties at the discretion of Document Control. Agendas are the documents that give those attending meetings prior notice of what is being discussed. Agendas also give all the relevant details (chi tiết liên quan) of when and where the meetings take place and who attends. Minutes are the formal record of what was decided at the meeting.

- Complete final distribution (phân phối sự kiện sau cùng trong một chuỗi sự kiện) of approved ECO within 10 working days of CCB approval

CCB Member Responsibilities:

- Review each ECO and develop relevant change impact information (phát triển thông tin có liên quan tác động thay đổi) considering Member’s organization

- Maintain a current charter (document) (duy trì một bản tuyên bố (văn kiện) hiện hành) which include identification of Member, two Alternate Members and Manager’s approval

- Provide ECO review feedback (duyệt lại thông tin dùng để cải tiến) to Originator prior to scheduled CCB meeting

- Attend each CCB meeting or, if unable to attend, appoint an Alternate Member

Change Consolidation: Document revision and engineering changes should be combined in the following method.

- Combined all concurrent changes to a part or assembly into a single ECO

- Group all parts and assemblies affected by a change into a single ECO

- Comply with the rules of interchangeability

NỘI DUNG TÀI TRỢ

Quảng Cáo Dịch Vụ

Quảng Cáo Sự Kiện

Quảng Cáo Khuyến Mãi

Biểu Trưng & Nhãn hiệu

Hỗ trợ chúng tôi và phát triển doanh nghiệp của bạn với chúng tôi. Mục tiêu của tôi là cung cấp thông tin kỹ thuật với khả năng truy cập sẵn sàng vào các tài nguyên, công thức và tài liệu tham khảo thường cần thiết trong khi thực hiện công việc của mình với tư cách là Kỹ sư hỗ trợ kỹ thuật. Các doanh nghiệp được liệt kê trong Nội dung được Tài trợ đã được lựa chọn cẩn thận vì tính độc đáo của chúng. Tuy nhiên, các quảng cáo liệt kê không được tài trợ sẽ được luân chuyển thay đổi hàng tháng.

ViBa Direct thiếu một ban cố vấn để thực hiện nghiên cứu và thuê các nhà văn với kiến thức kỹ thuật hiện đại. Việc tạo ra một ban cố vấn hiệu quả đòi hỏi nhiều hơn là một lời mời. Nếu không có sự tài trợ của bạn, điều này khó có thể thực hiện. Nếu công ty của bạn có nhu cầu quảng cáo, đặt biểu trưng, thương hiệu, biểu ngữ mời tham gia thảnh viên, hội viên cũng như các bích chương quảng cáo ở đây hoặc trên bất kỳ trang nào khác, xin vui lòng liên hệ với nhóm Dịch Vụ Khách Hàng Dịch Vụ Khách Hàng để biết thêm chi tiết.

Effectivity Principles: When effectivity (hiệu quả) is specified as a date, it’s the date when the change will be incorporated on the highest-level assemblies, kits or parts, indicated within the body of the ECO. Lower-level changes or activities to support the ECO such ordering, stocking of parts or reworking subassemblies may have earlier effectivity dates determined by Inventory Production Control Planning. Effectivity should reference a System Number where the change goes into effect. System Number is mandatory for reliability, retrofit, and rework ECOs.

The following factors determine effectivity: Pending ECOs - Drafting Backlog - Scrap Cost - Test Fixture – Material availability – Labor Availability – Procedures – Priority Modification.

ECO Originator's Responsibility: Originator can recommend effectivity based upon an assessment of the basic for change and its expected effect upon Manufacturing. Field Engineering, Materials, Spares, etc. Materials sets the effectivity date at CCB, and follows up with the first System Number affected, at least 5 days before effectivity date. Document Control will redistribute ECO cover sheet when starting System Number is added.

ENGINEERING CHANGE ORDER CATEGORIES

ECO change categories define the nature of the problem and identify the basic reasons for recommending a change. They are the only categories for change considered acceptable. If an ECO has two categories, the higher indicated approval class prevails (chiếm ưu thế). The ECO Form shows these categories.

Pre-Production ECO: Unreleased piece parts for production use. All new parts are structured to Engineering Project numbers. The numbering system is to be determined. The system parts into the Engineering Project number. Materials will procure (thu được, hiện hành, thông dụng) all new prerelease parts, and buy the released part conservatively. The Master Scheduler will ensure demand is added to PLM System to drive the appropriate requirement. This does not allow shipment; an ECO is required for Production Release.

Reliability: Changes required to overcome a failure to meet minimum requirements of the product design specification, or failing to meet accepted industry standards.

BOM Change: Change or add item numbers, reference designators or quantity on the BOM only, doesn’t affect drawing other than revision change.

New Product: Release of new products and options.

Product Improvement: Changes to improve product life, performance, maintainability, or capabilities which exceed the requirements of the existing product design specification.

Procurement: Changes required to overcome inventory shortages, supplier problems, or part availability.

Producibility: Changes required to overcome manufacturing difficulties BOM errors, etc.

Safety: Changes required to correct actual or potential personnel safety problems, damage to equipment or environment.

Defect: Changes required when a manufacturing defect occurs when something in the manufacturing process caused the product not to be made according to the design.

Rework: Changes required when a manufacturing rework to correcting defective, failed, or non-conforming items after inspection. This process includes responsibilities like disassembly, repair, replacement, reassembly, and more.

Excessive Scrap: Changes required to overcome the scrap count exceeds the amount allotted when the job was set up.

Obsolete Components: Changes required to overcome the need to outsource a different component based on the lack of availability of resources from outside vendor(s).

Compliance Violation: Changes required when any newly enacted laws affecting how the product performs in the market place, and whether those create a violation.

ENGINEERING CHANGE ORDER IN A NUTSHELL

ECO processing can be viewed as three basic steps: creation, approval, and implementation.

CREATION: Identifies a problem or issue and determines that it may require a change —» Originator —» Complete ECO form —» Update Revision Level —» Verify that ECO is correct and complete —» Obtain any necessary approvals from Engineer, Manufacturing, Quality, Scheduler, Marketing, Retrofit —» Document all procedures affected within ECO —» Completed ECO form —» Distribute ECO package to affected CCB members —» Create CCB meeting agenda —» Notify CCB members of meeting date and time —» Attend CCB meeting —» Review any changes or issues with CCB members —» Marked up ECO —» Approved ECO changes —»

APPROVAL: The ECO is circulated for review and discussion among key stakeholders and is modified as needed —» Document Control —» Enter ECO data into MRP system —» Update revision level, ECO number and Date of Release as required —» Maintain Master document and Master digital files and Backup as required —» Distribute ECO package to Distribution List —» Management approved ECO as requested includes R&D Engineer + Manufacturing Engineer + Purchasing + Material Planner + Planning Engineer + Electrical Engineer + Software Engineer + Quality Control + CCB Members —»

IMPLEMENTATION: Those responsible for implementation use the information in the ECO and ECN to make the requested change —» Engineering Release —» Pre-production —» ECO must go through CCB review + Engineering review + Manufacturing review + Quality review + —» Inactivating Part (bộ phận vô hiệu hóa, không hoạt động) or Obsoleting (bộ phận quá hạn, đã lỗi thời) Part.

ECO ACRONYMS / DEFINITIONS / TECHNICAL TERMS

Abandoned: The Abandoned status is an inactive status which indicates that a Design stage Item is no longer being worked on and should not be considered for new designs.

BOM: A comprehensive list of parts, items, assemblies and other materials required to create a product, as well as instructions required for gathering and using the required materials. The Bill of Materials (BOM) is the basic building block for manufacturing a part. A Bill of Materials can be comprised of three items: Components, Sub-assemblies, and Phantom BOM’s.

Change Order (CO): A generic term for all type of change orders.

Change Request (CR): Used to plan or execute design, process, supplier and/or supplier process changes.

Change Request Management: The change request management process in systems engineering is the process of requesting, determining attainability, planning, implementing, and evaluating of changes to a system. Its main goals are to support the processing and traceability of changes to an interconnected set of factors.

Complete: Moving a Change to the Completed phase signifies that all work and implementation activities are finished.

Component: Raw materials used to manufacture a product; typically items that are purchased from an outside vendor.

Deprecated: An Item in the Deprecated phase of the Item lifecycle is not recommended for use in new designs. A deprecated Item is typically on its way to obsolescence, but is not yet considered obsolete because it is still being produced and used. A common practive is to mark an Item as Depredacted for a limited time before obsoleting it, to discourage use in future design.

Design History File (DHF): The compilation of records that describes the design history of a finished device.

Design Master Record (DMR): A compilation of records containing the procedures and specifications for a finished device. DMRs shall include or reference the location of —›

‹•› Device specifications including appropriate drawings, composition, formulation, component specifications, and software speicifications.

‹•› Production process specifications including appropriate equipment specifications, production methods, production procedures, and production environment specifications.

‹•› Quality assurance procedures and specifications including acceptance criteria and the quality assurance equipment to be used.

‹•› Packaging and labeling specifications including methods and processes used.

‹•› Maintenance servicing procedures and methods.

Deviation: A deviation request requires that an alternative be submitted. A deviation refers to any departure from an approved instruction, procedure, established standard, or specification. Deviation can be of two different types: A) Planned Deviation B) Unplanned Deviation. Planned deviations are those deviations from the procedure that are planned and we know before they occur.

Document Change Order (DCO): A change order detailing modifications to documents, specifications, or SOPs.

Engineering Change Management (ECM): Engineering Change Management is a systematic approach to the documentation of changes from the identification of the required change, through the planning and implementation of the change, and culminating with the closure of the issue.

Engineering Change Notice (ECN): A document to authorizing and recording design changes throughout the prototyping and life-cycle phases of a product. Once the ECO has been approved, an engineering change notification/notice (ECN) is sent to affected individuals to let them know that the ECO has been approved and the change should now be implemented.

Effectivity Revision: The most recent released revision of an item.

Engineering Change Order (ECO): A change order that is used to track changes to items in the production level revision (alpha revision) within Change Management.

Engineering Change Request (ECR): A correction to address or fix the problem, what items would have to change to fix it, and signoffs to say the suggestions are approved and to move forward with the ECO process.

Engineering Design Specification (EDS): A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard. It is a common early part of engineering design and product development processes in many fields.

Engineering Purchase Specification (EPS): The characteristics that are associated with an item or product to be purchased. It can include weight, size and dimensions, quality, safety requirements and the products performance parameters.

Enterprise Resource Planning (ERP) system is an end-to-end process management system, also a central repository for documents, notes and communication for the whole company include: product lifecycle management, supply chain management, warehouse management, customer relationship management (CRM), sales order processing, online sales, financials, human resources, and decision support system.

Engineering Reference Specification (ERS): A specification that calls out a material, product or method based on the requirements of testing standards written by organizations such as ASTM, ANSI, UL, OSHA, etc.

Engineering Requirement Specification (ERS): An Engineering Requirements Document specifies how a product will be built in order to fulfill the PRD's multitude of wishes.

Engineering Specification (ES) or (ENSP) are the records which provide detailed documentation of the construction, wiring, arrangement and related engineering details of the information processing equipment.

Engineering Specification Waiver (ESW): A correction to a performance or safety deficiency for systems in the field. It is provided to the customer at no cost.

Engineering Units: A unit of measurement is a definite amount of a physical quantity defined and adopted by convention and or law, that is used as a standard for measurement of the same physical quantity of any amount. Examples of engineering units are seconds, degrees Celsius, Kilograms, Newtons etc. For example, the metric of braking distance may be measured in units of meters.

Initial Purchase Quantity (IPQ): Unreleased piece parts for production use. All materials and new parts for manufacturing a product first arrived into the warehouse under that Purchase Order Product record.

In-Process Quality (IPQ): Unreleased piece parts for production use. All materials and new parts for manufacturing a product are monitored and inspected before the manufacturing process is completed in order to comply with the specifications.

Incoming Product Quality (IPQ): Unreleased piece parts for production use. All incoming materials and new parts for manufacturing a product are monitored and inspected before the start of the manufacturing process to assure all products and materials meet or exceed internal and external customer specifications.

Manufacturing Change Order (MCO): A change order describing modifications to the manufacturing process or equipment. It is used to track modifications to the manufacturing process, equipment or sourcing (e.g. updating supplier information from a potential source relationship to an approved source relationship) without change to the form, fit or function of the item. This change does not affect the revision of the item.

Manufacturing Change Request (MCR): A change request specifying proposed modifications to the manufacturing process or equipment.

Nonconformance is defined as an output that doesn't meet specifications or requirements. There are two types of non-conformances- minor non-conformance and major-non-conformance. The difference is how many corrective measures you need to put in to get your organization back on course.

Nonconformance Report (NCR): A nonconformance report is a document that addresses specification deviation or work that fails to meet quality standards. The report is used for the quality control process, in which it details the problem, how it occurred, and how to prevent it from happening again.

Part Lists, also known as (BOM): Bill of Materials is an Engineering document containing a list of parts that make up an assembly and contribute to the cost of that assembly. Part Lists can have layers of hierachy that build up to the complexity of a completed product. Additionaly, part lists can include non-material parts such as labor or testing.

Phantom BOM’s: Another production BOM is used in conjunction (liên từ) with other BOM components or sub-assemblies. Phantom items are typically used in multilevel 'Bill of Materials' (BOM), where a single row of a phantom item serves the purpose of an entire sub-tree. These items do not exist in the inventory. They are designed to be used in situations where several BOMs would have the same basic components. Một Hoá đơn Nguyên liệu sản xuất khác được sử dụng cùng với Hoá đơn Nguyên liệu hợp thành (kết thành) hoặc các bộ phận lắp ráp phụ. Vật phẩm ảo thường được sử dụng trong 'Hoá đơn Nguyên liệu' đa cấp, trong đó một hàng duy nhất của vật phẩm ảo đáp ứng mục đích của toàn bộ Hoá đơn phụ. Những mặt hàng này không tồn tại trong kho. Chúng được thiết kế để sử dụng trong các tình huống mà một số Hoá đơn Nguyên liệu sẽ có các thành phần cơ bản giống nhau.

Obsolete: An Item in the obsolete stage of the Item lifecycle may not be used in any new designs. An obsolete Item may be re-activated using Re-Activated Item function or via a Change, depending on whether or not Change Management is required in the workspace.

Pending Revision: A lock-down revision that is scheduled to become the next effective revision at a future date upon effectivity of a change.

Phase is a period within a stage of an object's lifecycle. Items, Requests and Changes have predefined lifecycle stages and phases, but Account Administrators can customize the Item lifecycle by creating their own phases. Project phases are defined by the creator of a Project.

Procurement Process: The process of purchasing goods or services and is usually in reference to business spending. Business procurement requires preparation, solicitation, and payment processing, which usually involves several areas of a company.

Product Engineering Specification (PES): The product engineering specification (or product design/requirements specification, often “spec”) is a critical document in the creation of every product. Specifications are quantitative, measurable criteria that the product is designed to satisfy. PES must contain a metric, target value and engineering units for the target value.

Product Improvement Kit (PIK): Equipment needed to enhance the system, purchased by customer for a system in the field. Require field services can be provided or self-installed.

Quality Function Deployment (QFD): Quality Function Deploymentis a model for product development and production popularized in Japan in the 1960's. The model aids in translating customer needs and expectations into technical requirements by listening to the voice of customer. QFD is a systemmatic way of obtaining information and presenting it. The benefits of QFD is fewer engineering changes and shorter product development cycle.

Retrofit: A correction to a performance or safety deficiency for systems in the field. It is provided to the customer at no cost.

Request for Waiver (RFW) is a request for authorization to accept an item which, during manufacture or after inspection is found to depart from specified requirements, but neverthe less is considered suitable for use as is or after repair by an approved method.

Submitter: Person submitting th Change Order. This can be different from the Initiator.

Target Value is the range of the metric that is acceptable, Examples of target values include “less than 6 seconds”, “greater than 7 pounds” or “between 20 and 50 Kilograms”. For the braking distance example, the range of acceptable values might be less than 30 meters.

Unique Device Identifier (UID): An identifier that adequately idnetifies a device through its distribution and use by meeting the requirements 830 FDA Unique Device Identification System. A unique device identifier is composed of —›

‹•› A device identifier: A mandatory, fixed portion of a UDI that identifies the specific version or model of a device and the labeler of that device; and

‹•› A production identifier: A conditional, variable portion of a UDI that identifies on or more of the following when included on the label of the device —›

- The lot or batch within which a device was manufactured.

- The serial number of a specific device.

- The expiration date of a specific device.

- The date the specific device was manufacturered.

Waiver: A specific written authorization to omit (waive) a particular Standard, Procedure, Process, or Form, or portion thereof.

Work Instruction (WI): A document containing low level procedure details that specify how a task is to be performed, in order to implement and support policies/SOPs. Formal document change control is required for all WIs.

Working Revision: The editable revision of an item, where users make changes. There is only one working revision at a time.

Your Support Can Help Us Grow. Thank you for visiting ViBa Direct. As part of our commitment to continually improving the visitor experience. I am writing to ask you for your support, such as listing your company here with us. Clearly there is a great deal of manufacturers and distributors including both mechanical and electrical. Unfortunately, I don't have enough manpower to meet everyone needs. But if you are interested in finding out how to support us. Please provide details about your products and reach out to Customer Service, as well as any offerings that you feel may meet customer needs. Thank you in advance for taking the time to read this. Feel free to contact us with any additional feedback you would like to share about your experience visiting ViBaDirect.com.