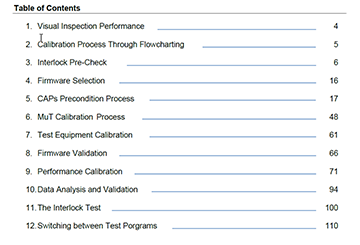

OPERATIONAL METHOD SHEET or OMS

What is Operational Method Sheets? It's a work instruction used to illustrate work flow of SOPs. OMS is a document primarily designed for editting and management a set of technological procedures, pictures and other instructions for each product that are placed at the workplaces. The procedures can be view electronically on production line – assembly line – test station monitors. Operational Method Sheets can be output as a PDF document with operations and illustrative photographs which is designed to be printed out or displayed directly on the assembly floor monitor. With electronic version displayed on a monitor there is no needed to print out anything and there is always an update revision of the OMS immediately at the work place.

The procedures can be view electronically on production line – assembly line – test station monitors. Operational Method Sheets can be output as a PDF document with operations and illustrative photographs which is designed to be printed out or displayed directly on the assembly floor monitor. With electronic version displayed on a monitor there is no needed to print out anything and there is always an update revision of the OMS immediately at the work place.

It is always more cost efficient to get the job done right the first time. Lean concepts can save you time, improve the quality of your work, and increase your value, no matter where you work or what your job description. The purpose of capturing only the valued-added activities and necessary activities is to synchronize all of the manufacturing processes so there is no downtime and copy exact of assembly procedures and validation test methods can be preformed as smoothly as possible. An effective OMS should have: Standardization of the data contained within | A controlled language to be used in the authorship of assembly instructions | A sustainable method for linking part, tool, and fixture information with assembly processes.

SPONSORED CONTENT

Your Service Flyer

Your Event Invitation

Your Promotion Ads

Your Logo & Brand

Support us and grow your business with us. My goal was to make technical information available with ready access to commonly needed resources, formulas, and reference materials while performing my work as a Technical Support Engineer. The businesses listed in Sponsored Content were carefully selected because of their uniqueness. However, non-sponsored selected ads will be rotated monthly.

ViBa Direct lacks an advisory board to do research and hire writers with the latest technical knowledge. Creating an effective advisory board requires more than an invitation. Without your sponsorship, this is not possible. If your company is interested in placing the company’s logo, brand, event invitation, and other promotional banners and flyers here or on any other pages, please reach out to Customer Service for more detail.

OMSDOD: "Operational Method Sheets Display On Demand". Manufacturing work instruction sheets for assembly lines – test stations – operator training classes. OMSs are minimal written instructions in sequential steps that describe work to be done with electronic images to show or demonstrate how work is to be carried out. Electronic images are combined with a written instruction in a consistent format for easy and rapid comprehension. Online presentation provides work instructions and operational method sheets in real-time. The paperless system ensure that each process is done correctly the first time, and every time. Online work instruction system make new assembler training effortless. Step-by-step Work Instruction sets are displayed on demand. OMS creation and revision should be focused on delivering value to the customer, but never at the expense of the employee.

Standardization of Operational Method Sheet Information:

‹•› 1st Objective: Define use cases for OMSs | Analyze existing OMSs | Develop data model for standardized OMSs.

‹•› 2nd Objective: Analyze language used for assembly instructions on current OMSs | Analyze existing OMSs | Develop data model for standardized OMSs.

Controlled Language: The authorship of assembly steps must facilitate automated translation of text. This translation must be done using OEM specified translations in order to ensure interpretability and consistency of translations. Assembly instructions contained within OMSs are created without restrictions on grammar, diction, or level of detail of the assembly steps will makes:

› › The interpretation and translation of assembly instructions difficult. Assembly instructions vary between different author. Hence, the controlled language is used to eliminate the inconsitency in assembly instruction (Do đó, ngôn ngữ được kiểm soát được sử dụng để loại bỏ sự không nhất quán trong hướng dẫn lắp ráp). The specification of a controlled language must facilitate automated translation of text, must support periodic updates to the vocabulary, must dynamic so that new parts, tools, fixtures or other objects changes can be accommodated. However, the controlled language should not diverge to such a large vocabulary that multiple terms are defined for a single object or action.

› › The link between assembly steps and process time evaluations is lost. Assembly steps should be directly linked to a task or set of tasks. A functional OMS management system should include a method to reduce the amount of manual labor required to keep operationa method sheets up to date with the latest part, tool and fixture information.

› › The link between assembly steps and the parts, tools, fixtures, or other physical items required to complete the step is lost. Uses of free text during assembly instruction authorship allows different process planners to refer to the same physical object with different vocabulary, which is often inconsistent between different planners and results in confusion for the associates performing the assembly process.

› › New objects used in assembly processes are described differently by different process planners. Parts and tools are updated frequently, thus the way in which process planners author assembly steps may also change.

Hence, the controlled language is used to eliminate the inconsitency in assembly instruction (Do đó, ngôn ngữ được kiểm soát được sử dụng để loại bỏ sự không nhất quán trong hướng dẫn lắp ráp). The specification of a controlled language must facilitate automated translation of text, must support periodic updates to the vocabulary, must dynamic so that new parts, tools, fixtures or other objects changes can be accommodated.

WRITTING OPERATIONAL METHOD SHEET

Writing Operational Method Sheets should be written in a concise, step-by-step, easy-to-read format. The information presented should be unambiguous and not overly complicated. The active voice and present verb tense should be used. The term "you" should not be used, but implied. The document should not be wordy, redundant, or overly lengthy. Keep it simple and short. Information should be conveyed clearly and explicitly to remove any doubt as to what is required. Also, use a flow chart to illustrate the process being described. In addition, follow the style guide used by your organization, e.g., font size and margins. To write the Standard Operation Procedure —»

‹•› Select Operation that is easily to manufacture, low labor cost, and consistencies in quality + manuacturing, + testing times. "What are you looking to achieve?"

‹•› Select Operation that is easily to manufacture, low labor cost, and consistencies in quality + manuacturing, + testing times. "What are you looking to achieve?"

‹•› Record Data of Operation methods include —» video recording, interview, flow process charts or historical records. When recording the procedure, direct observation is prefered.

‹•› Analyse the Operation —» gather all the relevant documents + observe operation being performed + ask for the technicians inputs, and take rough notes. "Colaborative Creation".

‹•› Develop the Best Method important key questions include: What tasks do we need to do? —» Who needs to do them —» What are the best ways to approach these task? —» Can the operators follow the Standard Operation safely? "Map a Process Flow Diagram".

‹•› Confirming the Steps should be carried out in the production environment where possible as a complete operation of how a prototype will look, feel and work in the real world —» "Identify Main Steps": A task Title, this will allow the task to be broken down into smaller sections. —» "Identify Key Points": Key Points are part of the operation, relevant information/steps which could impact on QUALITY–SAFETY or DELIVERY. Points of which would seriously affect the production or the success of operation.

‹•› Graphical and Intutive instructions for technicians, operators, material handlers, assemblers, workers, etc.

‹•› Graphical and Intutive instructions for technicians, operators, material handlers, assemblers, workers, etc.

‹•› Improve Quality –» OMS helps to improve standardi all work processes: References — Training — Quality — Audit.

‹•› Work Process Knowledge –» Hand-ons knowledge are best capture visually instead of lengthly flow charts.

‹•› Copy Exact –» OMS helps make a difference for parts produced in large quantity.

‹•› PFEMA Achievable –» Possibility to achieve quality document with rigorous Process Failure Mode and Effect Analysis.

‹•› Sustainable: Active documents to be maintain by Engineers, Supervisors.

‹•› Document Control –» Change Management Process is required and to be audited. OMS directly provide the value-added activities, so Quality Audit of OMS is focal.

‹•› Redline –» Red colour strikeout text, picture and addition changes can be implemented quickly in OMS for assembly floor for quick-turn-around cases while pending formal EC process.

‹•› The OMS Checklist is a helpful tool that can be used by the OMS Author to improve the quality of the OMS. Use of the OMS Checklist is strongly recommended prior to OMS release.

OPERATIONAL METHOD SHEET ADMINISTRATION

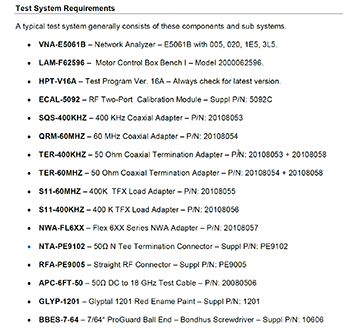

User Interface: OMSs are stored in a SQL server database and their editing is only possible via a web interface. This secures that each document is available only in a single unfinished or in a single authorized version. The stored documents should be stored in a clear tabular form where the entire document for a particular product or department.

Adding and Editing: It is possible to use editor templates, defined precisely to the standards provided by the company, or the OMS Spreadsheet module which makes it possible to work with spreadsheets (Excel/Google) in the web browser environment.

Application Output: Graphical and Intutive instructions output is a PDF document with the relevant operations and illustration photographs to be printed out or it is possible to display it directly on a monitor at the workplace by means of the OMS Browser application. The benefit of electronic version are: No hardcopy to print out | Update on the fly | Convenience and available immediately.

Sequence Definition: The technological procedures which are added to the system by means of templates can be linked to the parts list. The technologist picks up the individual parts and matches them with the operations defined for each workplace of the production line.

Picture-In Picture Editor: Developing subject...

SPONSORED CONTENT

Quảng Cáo Dịch Vụ

Quảng Cáo Sự Kiện

Quảng Cáo Khuyến Mãi

Biểu Trưng & Nhãn hiệu

Hỗ trợ chúng tôi và phát triển doanh nghiệp của bạn với chúng tôi. Mục tiêu của tôi là cung cấp thông tin kỹ thuật với khả năng truy cập sẵn sàng vào các tài nguyên, công thức và tài liệu tham khảo thường cần thiết trong khi thực hiện công việc của mình với tư cách là Kỹ sư hỗ trợ kỹ thuật. Các doanh nghiệp được liệt kê trong Nội dung được Tài trợ đã được lựa chọn cẩn thận vì tính độc đáo của chúng. Tuy nhiên, các quảng cáo liệt kê không được tài trợ sẽ được luân chuyển thay đổi hàng tháng.

ViBa Direct thiếu một ban cố vấn để thực hiện nghiên cứu và thuê các nhà văn với kiến thức kỹ thuật hiện đại. Việc tạo ra một ban cố vấn hiệu quả đòi hỏi nhiều hơn là một lời mời. Nếu không có sự tài trợ của bạn, điều này khó có thể thực hiện. Nếu công ty của bạn có nhu cầu quảng cáo, đặt biểu trưng, thương hiệu, biểu ngữ mời tham gia thảnh viên, hội viên cũng như các bích chương quảng cáo ở đây hoặc trên bất kỳ trang nào khác, xin vui lòng liên hệ với nhóm Dịch Vụ Khách Hàng Dịch Vụ Khách Hàng để biết thêm chi tiết.

Drawing Browser: Production processes may include drawings that can be viewed in the web browser environment with the support of zoom function and unhindered shifting in al directions.

OMS Properties: On behalf of the technological procedures that rely on the parts lists, the application monitors any changes in the parts lists and notifies the technologists responsible. With each edited document the system stores an audit log which shows who, when and how has edited the document

Sustainable: Products that provide environmental, social and economic benefits while protecting public health and environment over their whole life cycle, from the extraction of raw materials until the final disposal.

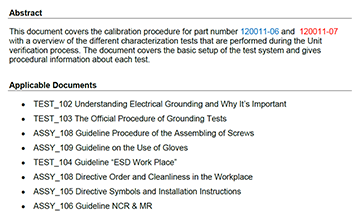

Document Control is focal. Document control can refer to a document management profession or a practice for managing product and quality related documentation. A document should be controlled if there are regulatory compliance requirements specifying the practices for creating, managing, distributing, and disposing of documents.

The OMS Checklist is a helpful tool that can be used by the OMS Author to improve the quality of the OMS. Use of the OMS Checklist is strongly recommended prior to OMS release.

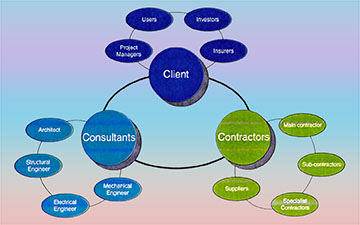

Authorize the OMS. Usually certain Production Manufacturing Engineers, Test Engineers and other field experts are authorize. Sequence of Events (SOE) The sequence-of-events (SOE) are a list of work instructions. They are listed sequentially in Excel sheet. Each work task can be broken down into sub-tasks. The format includes:

OPERATIONAL METHOD SHEETS FORMATTING

A picture is worth a thousand words. Technical instruction, technical report or assembly instruction can be written without some form of graphic display to support the text. But incorporate graphics into your OMS or technical presentation can remove many words to explain something. Graphics can be used to represent the following elements (objects, numbers, instructions, and choices) in your technical writing. Photographs, drawings, diagrams, and schematics are the types of graphics that show objects. There are several formatting requirements to follow.

‹•› Titles: Most visual aid use should have a title. The titles of all the illustrations should be numbered. If you only have one or two illustrations, then you might want to keep the title but discard the word "Figure" and the number following it. All illustrations that describe something should contain labels. That is, words and phrases with pointers that name the parts of the things being described.

‹•› Keys: Illustrations, like bar or pie charts, have certain shadings, colors, or line styles, that have a special meaning, these should be indicated in a key. That is, an area in an unused corner of the illustration that lists and describes their meaning.

‹•› Sequence Number of work task. A sequence is an enumerated collection of objects in which repetitions are allowed. Like a set, it contains members (also called elements, or terms). The number of elements (possibly infinite) is called the length of the sequence. Unlike a set, the same elements can appear multiple times at different positions in a sequence, and order matters.

‹•› Find Number to indicate visual images of work tasks – Description of work task or sub-task – Material needed – Tooling required

Your Support Can Help Us Grow. Thank you for visiting ViBa Direct. As part of our commitment to continually improving the visitor experience. I am writing to ask you for your support, such as listing your company here with us. Clearly there is a great deal of manufacturers and distributors including both mechanical and electrical. Unfortunately, I don't have enough manpower to meet everyone needs. But if you are interested in finding out how to support us. Please provide details about your products and reach out to Customer Service, as well as any offerings that you feel may meet customer needs. Thank you in advance for taking the time to read this. Feel free to contact us with any additional feedback you would like to share about your experience visiting ViBaDirect.com.