Explore the best in lifestyle literature—from ART and TRAVEL to CULINARY and CULTURE. Build a wardrobe to match our collection of women's clothing, created for lasting style and today's trends. Books & Fashion Boutique

Check out THE NEW ARRIVALS

Check out THE NEW ARRIVALS

⭐⭐⭐⭐ YOUR AD COULD BE NEXT!

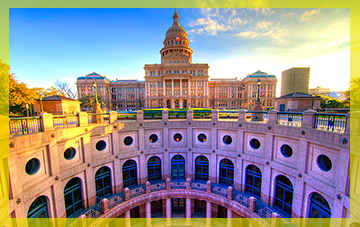

BULLOCK MUSEUM in Austin, Texas houses a 300-year-old shipwreck, a French colonial ship that sank in 1686 while explorer the Mississippi River. The museum features one of the biggest IMAX screens in Texas.

ACL MUSIC FESTIVAL draws about 450,000 attendees over two weekends. The festival is famous for ACL Eats, which exclusively features a wide selection of food, drink, and sweets from Austin's.

AUSTIN VISITORS GUIDE. The Congress Avenue Bridge is where to see the bats at sunset! The best time to see them emerge is right at sunset or slightly after from mid-March through early November).

Check out EXCLUSIVE OFFERS

Check out EXCLUSIVE OFFERS

HEART FIJI PINK SWEATER

BLUE OPAL TREND FLEECE

SALMON ROSE SPLIT-NECK TOP

⭐⭐⭐⭐ SAN FRANCISCO BAY, CA

PHIL'S FISH MARKET & EATERY is a famous, long-standing seafood restaurant & fish market, best known for its award-winning Cioppino. "One of the 5 Best Beach Restaurants in the World" – BBC Travel.

SAN FRANCISCO BIKE RENTAL is located near Fisherman's Wharf conviniently for a full day of exploring the famous National Park Bike Path, the Presidio and over the Golden Gate Bridge to Sausalito.

MONTEREY BAY AQUARIUM is located directly on the edge of the Monterey Bay National Marine Sanctuary, creating a truly authentic environment for a Living Kelp Forest and its Open Sea exhibit.

Check out THE BOOK SALE

Check out THE BOOK SALE

CATS IN CROSS STICH

PAINTING STILL LIFE

PARTY FOOD